TERRA LABORATORIES

Renewable bio-Plastics & ChemicalS

RBP - Renewable Bio Plastic

Terra Laboratories developed carbon-neutral RNB technology. Subsurface microbes are genetically modified to consume hydrocarbon waste or oil to produce biodegradable plastic.

ESG

Terra Laboratories provides measurable insights that others don’t. We will help you measure, analyze and improve you ESG rating

MEOR | BioEOR | RNG |

MEOR – Microbial Enhanced Oil Recovery | Bio Tracers | BioEOR – Biologically Enhanced Oil Recovery & Insitu Refining Technology | RNG – Renewable Natural Gas | EOR & IOR | Real-Time Production & Frac Diagnostics |

Geothermal

Derive core-like quality insights from cuttings | Reservoir & Geomechanical properties | Rock & Fluids Fingerprinting | Identify landing targets |

Oil & Gas, Mining Lab Services

XRD – Mineralogy & Clay Speciation | WD XRF Elemental Analysis | FIMB | HAWK Pyrolysis | DNA Sequencing | Water Analysis | CST RO | Microfluidics | Oil, Water & Gas Fingerprinting | High-Resolution Cuttings Analysis |

Novel Engineering Solutions

FreeFlow – cutting-edge non-invasive wax, scale & corrosion control technology | ThermaFlow – innovative induction heating cable, prevents wax solidification in pipeline |

RENEWABLE

BIO PLASTIC

RBP – Renewable Bio-degradable Plastic

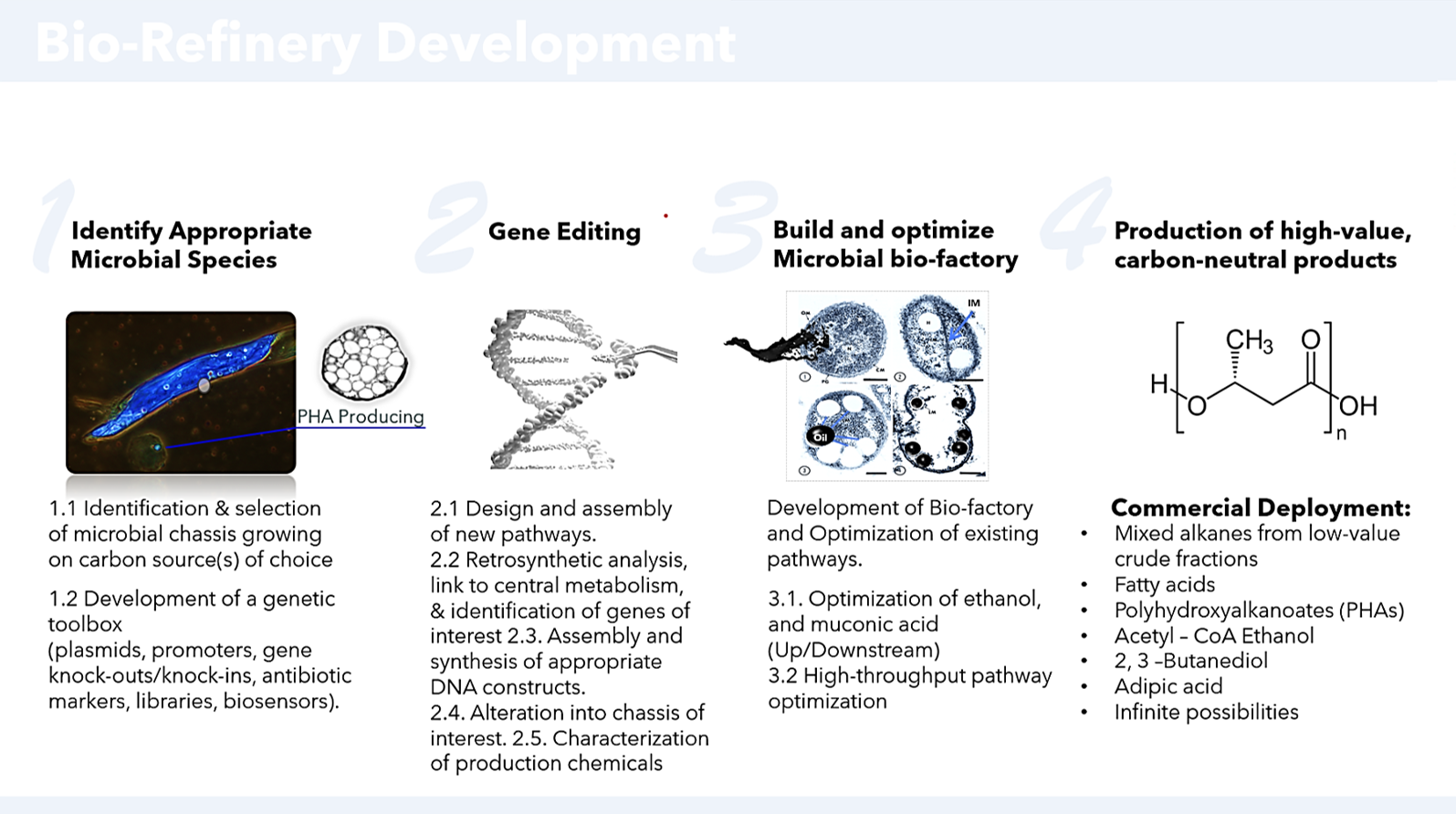

Terra Laboratories has developed an innovative carbon-neutral and cost-effective Bio-Refinery technology for the production of RBP.

Recent advances in synthetic biology provide the opportunity to develop super microorganisms capable of producing a variety of PHAs and high-value chemical products at low cost.

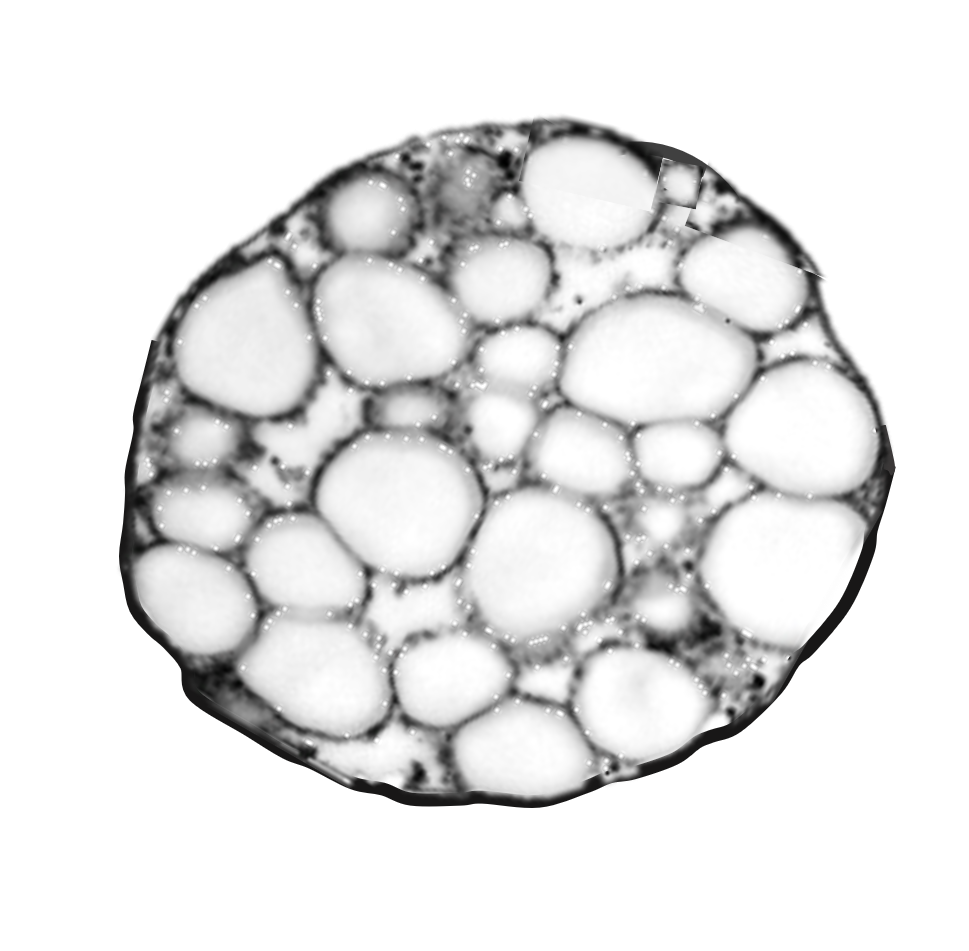

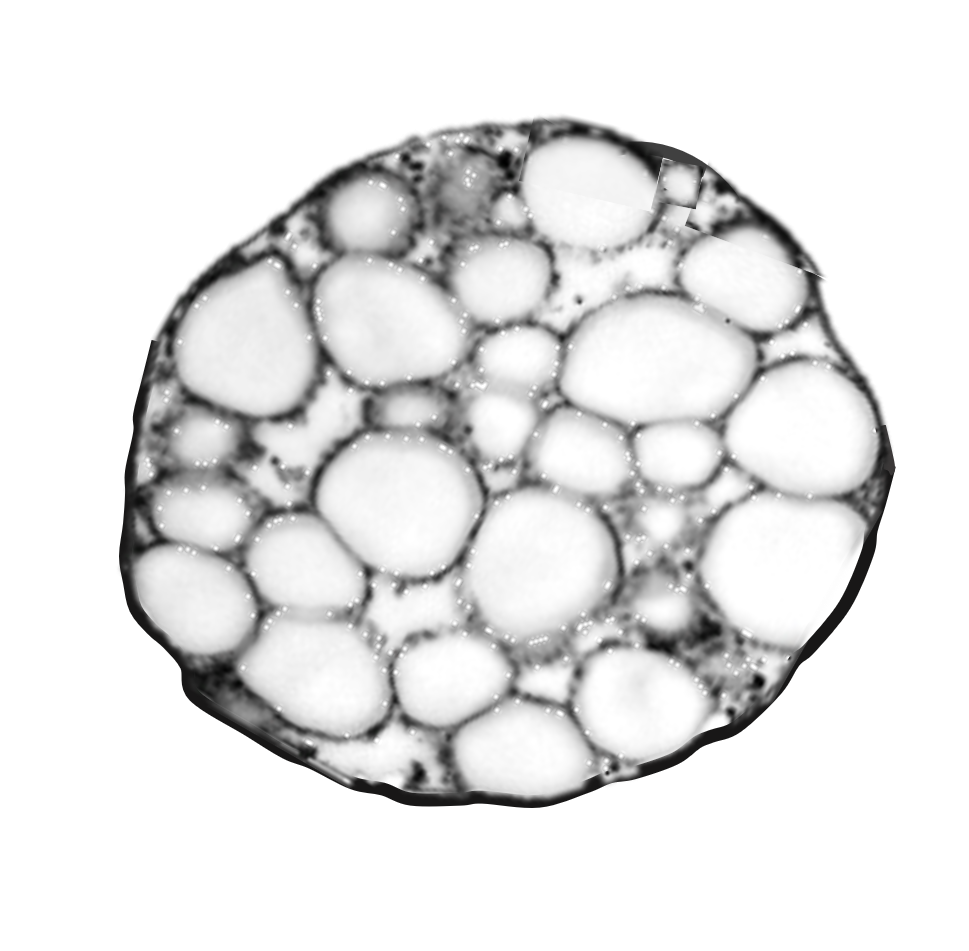

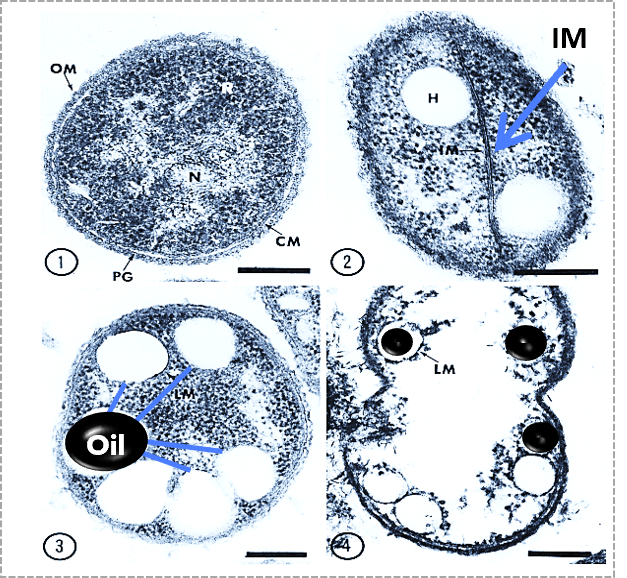

At Terra Laboratories, we modify the DNA of unique species of subsurface bacteria and archaea recovered from oil and gas reservoirs. Gene editing allows bacteria to rapidly grow to high cell densities and produce PHAs with diverse properties and high carbon source to PHA conversion efficiency.

Our micro-organisms consume hydrocarbon waste, low grade crude oil or CO2 to produce biodegradable plastics and valuable chemicals.

Goal:

Produce BioPlastic from HC waste, Oil, and CO2

Biologically convert the complex crude fractions, hydrocarbon (HC) waste and CO2 to high-value, carbon-neutral chemical products. PHAs are renewable and biodegradable plastics naturally generated by unique bacterial species as storage materials.

How?

Production of chemicals using proprietary bio factories.

Biorefineries composed of genetically-enhanced unique bacterial species convert complex crude oil fractions, captured CO2, and methane into high-value, carbon-neutral chemicals. Mixed alkanes from low-value crude fractions, Fatty acids, Polyhydroxyalkanoates (PHAs), Acetyl – CoA, Ethanol, 2, 3 -Butanediol, Adipic acid. Infinite possibilities.

High Value Products

INNOVATIVE CARBON NEUTRAL

Bio-Refinery

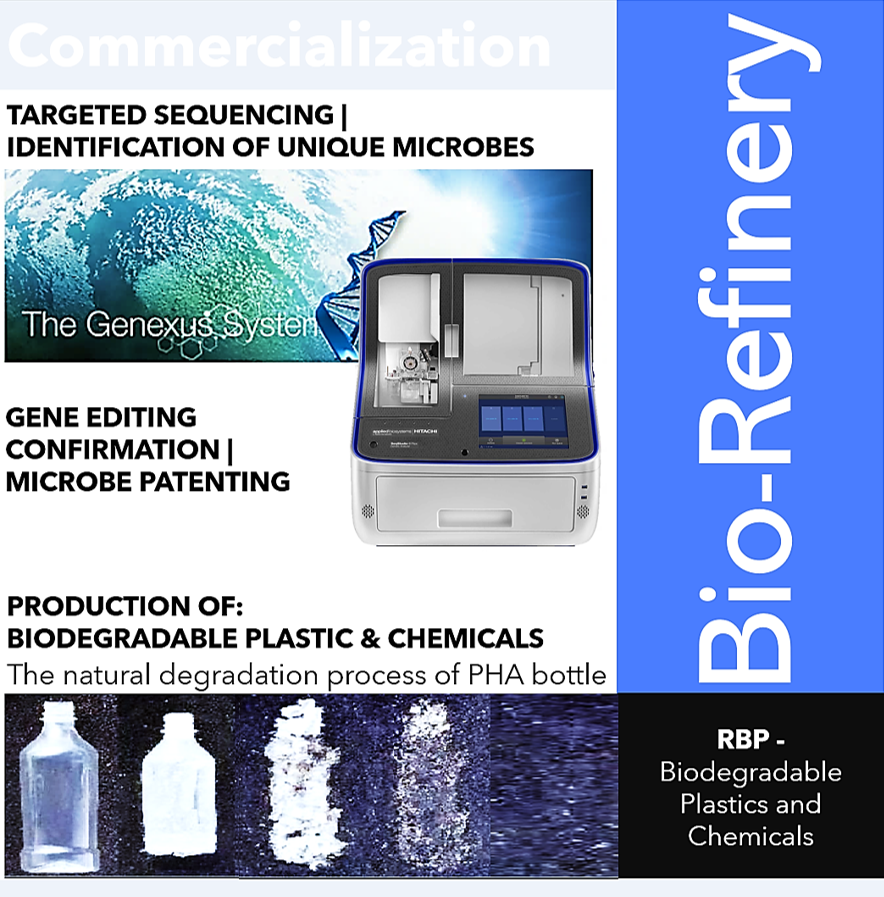

DNA Sequencing

RBP & high-value chemical products produced by genetically enhanced bacterial species.

Full genome sequencing of subsurface derived archaea and bacteria allows identifying unique species capable of generating PHA’s and other high-value chemical compounds. These microbial species are extracted from oil & gas reservoirs where they live in extreme conditions (high salinity, high temperature, oxygen deprived environment), making them ideal bio-refinery candidates.

High-Resolution Full Genome DNA Sequencing

DNA sequencing allows for identifying unique Insitu microbial species not detectable by standard methods . High-Res full genome sequencing helps identifying species that matter.

Proprietary Bioinformatics Platform & Custom Reagents

This method allows for estimating Producible OOIP, measuring Fluid Saturation of Mobile Oil, determining Sorbed Immobile Oil, breaking down

DNA Tracers

Applicability: Oil & Gas, Mining, Geothermal, Environmental. Subsurface bacteria can be used as natural non-depleting tracers and biomarkers. Microbial species change with changes in temperature, mineralogy, oil, water, and gas saturation, fluid composition, and ore concentration. There are hundreds of identifiable microbial species Insitu, making them ideal biomarkers. Microbial DNAs are used as “fingerprints” or natural tracers for production allocation & reservoir continuity purposes, to identify active faults, validate commercial saturation of hydrocarbons, and ore concentration.

DNA Tracers and Sweep Efficiency: This innovative method allows monitoring of wells throughout the life of the project without the need to pump additional chemical tracers. During secondary oil recovery (waterflooding), bacterial tracers provide information about reservoir sweep efficiency & communication between wells. The affordability of this method allows for continuous monitoring of wells at the pilot stage & throughout the project’s life field-wide.